490Mpa Gacan Electrode ah oo loogu talagalay birta xoogga sare leh

Codsiga&Standard&Ogaysiis

1. Ku haboon alxanka birta kaarboon iyo birta alwaax hoose, iyo sidoo kale XOOGGA ISKU DHACA EE BOILEERKA, dhuumaha, gaadiidka, DHISMAHA, BUNNADA IYO QAABKA kale, sida Q345.

2. Heerarka aan la kulanay: GB/T5117 E5018, AWS A5.1 E7018 & A5.1M E4918, ISO2560-A:E 42 3 B 3 2, ISO 2560-B: E4918 A

Maadaama E7018 electrode si fudud u nuugo qoyaanka, waxaa lagu hayaa foornada qalajinta korantada. Electrode-ka lagu kaydiyo hawada waxaa dib loo dubi karaa at 350 ~ 400 ℃ 1h ~ 2h. Si loo soo celiyo sifooyinka maqaarka. Birta khafiifka ah waxaa lagu alxan karaa korantado E7018 ah oo aan la duban, laakiin xoogga alxanka ee kama dambaysta ah waxa laga yaabaa in aanu ku filnayn.

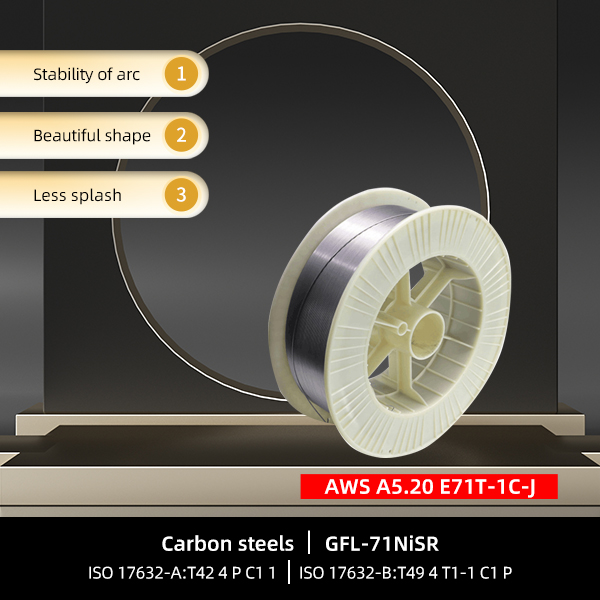

Astaamaha

Budada birta nooca ugu hooseeya ee gacanta electrode, wax ku oolnimada alxanka sare, qaanso xasiloon, samaynta quruxda badan, corrugations, daadinta yar, de-slagging fudud, caabbinta dabka maqaarka ee daroogada wanaagsan, caabin stomatal fiican. Guryaha farsamada ee xasiloon, caag wanaagsan iyo adkaysiga saamaynta heerkulka hooseeya.

E7018 waa koronto bir kaarboon ah oo tayo sare leh leh budada birta oo daahan yar oo potassium hydrogen ah. Electrode-ku wuxuu leeyahay qaab dhismeedka alxanka heer sare ah, qallafsanaanta arc waa wanaagsan tahay, ma fududa in la soo saaro eexda magnetic, tollaynta alxanka oo sameysa nadiif nadiif ah oo qurux badan, daadinta yar, slag waa sahlan tahay; Birta alxanka ayaa leh heerkul aad u fiican oo deggan iyo adkeysi dildilaac ah. Isticmaalka laba-geesoodka ah ee AC iyo DC, waxay sii wadi karaan alxanka booska oo dhan. Dabeecaddeedu waa in maqaarka daroogada uu ka kooban yahay budada birta, taas oo yareyn karta tirada lakabyada alxanka. Ku dub elektrodka 350 ~ 400 darajo Celsius 1 ~ 2 saacadood, isticmaalna dubista. Guud ahaan electrode this tayo sare leh waxaa loo isticmaalaa alxanka markabka birta (A, B, D ama E, A36, E36) iyo dhismayaasha muhiimka ah ee birta daawaha hoose ee darajada la mid ah xoogga, sida kuleyliyaha, weelasha cadaadiska iyo dhufto ee qodista xeebaha. iwm.

Shirkadda & Warshada

Halabuurka badeecada iyo soo bandhigida sifooyinka farsamada

QALABKA Kiimikada:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| XEERARKA GB/T | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| XEERARKA AWS | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| TUSAALE QIIMAHA | 0.075 | 1.17 | 0.5 | 0.04 | 0.02 | 0.007 | 0.017 | 0.009 | 0.01 |

HANTIDA makaanikada:

| HANTIDA | XOOG BADAN (MPa) | XOOGGA KORDHINTA (MPa) | KULULKA℃xh | ELONGATION(%) | ||||||

| XEERARKA GB/T | 400 | 490 | AW | 20 | ||||||

| XEERARKA AWS | 400 | 490 | AW | 22 | ||||||

| TUSAALE QIIMAHA | 460 | 555 | AW | 30 | ||||||

XILDHIBAANADA ALXANKA LAGU SOO TALIYEY:

| QAYBAHA DHUL-DHAQAALAHA (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| Koronto | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

FIIRO GAAR AH:

H/W: alxanka booska toosan

O/W: alxanka booska madaxa ka sarreeya

Kiisaska caadiga ah

Shahaado

Halabuurka badeecada iyo soo bandhigida sifooyinka farsamada

QALABKA Kiimikada:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| XEERARKA GB/T | 0.15 | 1.6 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| XEERARKA AWS | 0.15 | 1.25 | 0.9 | 0.2 | 0.3 | 0.3 | 0.035 | 0.035 | 0.08 |

| TUSAALE QIIMAHA | 0.075 | 1.17 | 0.5 | 0.04 | 0.02 | 0.007 | 0.017 | 0.009 | 0.01 |

HANTIDA makaanikada:

| HANTIDA | XOOG BADAN (MPa) | XOOGGA KORDHINTA (MPa) | KULULKA℃xh | ELONGATION(%) | ||||||

| XEERARKA GB/T | 400 | 490 | AW | 20 | ||||||

| XEERARKA AWS | 400 | 490 | AW | 22 | ||||||

| TUSAALE QIIMAHA | 460 | 555 | AW | 30 | ||||||

XILDHIBAANADA ALXANKA LAGU SOO TALIYEY:

| QAYBAHA DHUL-DHAQAALAHA (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| Koronto | H/W | 80-110 | 100-130 | 130-180 | 180-230 | ||||

| (Amp) | O/W | 50-80 | 90-120 | 130-160 | - | ||||

FIIRO GAAR AH:

H/W: alxanka booska toosan

O/W: alxanka booska madaxa ka sarreeya