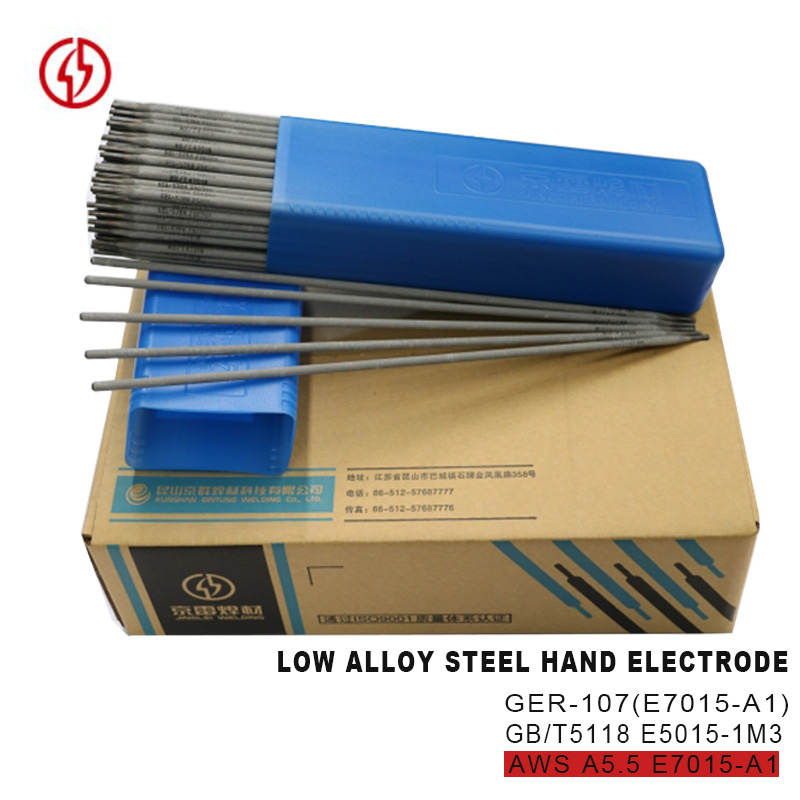

AWS E7015-A1 Biraha daawaha hooseeya ee gacanta alxanka alxanka

Codsiga&Standard&Ogaysiis:

E7015 nooca daawaha hoose ee gacanta electrode ku haboon alxanka heerkulka shaqada ka hooseeya 510 ℃ tuubada kulaylka, kulaylka iyo marar kale, sida ASTM A204 iyo A335-P1 tuubada;

Electrode waa in la qalajiyo ka hor inta aan la isticmaalin, hay arc gaaban, isticmaalka habka alxanka hore, ka fogow dhacdooyinka porosity at arc; Haydarojiin hooseeya waa in lagu hayaa inta lagu jiro habka alxanka. Xulashada korantada birta daawaha hoose, sida caadiga ah marka loo eego halabuurka kiimikada ee birta, guryaha farsamada, iska caabinta dildilaaca iyo shuruudaha kale, laakiin sidoo kale ka soo baxa qaab dhismeedka alxanka, xaaladaha shaqada, walbahaarka iyo qalabka alxanka iyo dhinacyada kale ee tixgelinta dhamaystiran. Haddii loo baahdo, imtixaanada waxqabadka alxanka waa in la sameeyaa si loo go'aamiyo electrode iyo tallaabooyinka lagama maarmaanka ah waa in la qaado.

Astaamaha

1. sodium hydrogen electrode hooseeya, ku daray 0.5% Mo si loo hagaajiyo xoogga alxanka iyo caabbinta daxalka;

2. Qandho xasiloon, firidh yar, samaynta wanaagsan, si sahlan loo jajabiyo, waxqabadka X-ray waa mid aad u fiican.

Guud ahaan dooro electrode u dhiganta si waafaqsan xoogga darajada birta ah, isla mar ahaantaana sidoo kale u baahan tahay in ay birta weldability, kala guurka ee qaybaha biraha waalidka, dhiirato in ay ka jawaabaan size qaab-dhismeedka, qaabka, jeexdin iyo arrimaha fiirsashada stress, sida dhamaystiran tixgelin, xawaaraha qaboojinta ee alxanka waa mid aad u weyn, waa xoog sare, alaabta wadada alxanka si fudud dillaaca xaaladaha xun, inta badan dooran kartaa qaar ka mid ah wax ka yar xoogga electrode biraha waalidka.

Shirkadda & Warshada

Halabuurka badeecada iyo soo bandhigida sifooyinka farsamada

QALABKA Kiimikada:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| XEERARKA GB/T | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| XEERARKA AWS | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| TUSAALE QIIMAHA | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

HANTIDA makaanikada:

| HANTIDA | XOOG BADAN (MPa) | XOOGGA KORDHINTA (MPa) | KULULKA℃xh | QIIMAHA IIMAPACT J/℃ | ELONGATION(%) | |||||||||

| XEERARKA GB/T | 390 | 490 | 620*1 | - | 22 | |||||||||

| XEERARKA AWS | 390 | 490 | 620*1 | - | 22 | |||||||||

| TUSAALE QIIMAHA | 477 | 570 | 620*1 | 150/Heerkulka caadiga ah | 28 | |||||||||

XILDHIBAANADA ALXANKA LAGU SOO TALIYEY:

| QAYBAHA DHUL-DHAQAALAHA (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| Koronto (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

FAAHFAAHINTA XIDHIIDHKA:

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||

Kiisaska caadiga ah

Shahaado

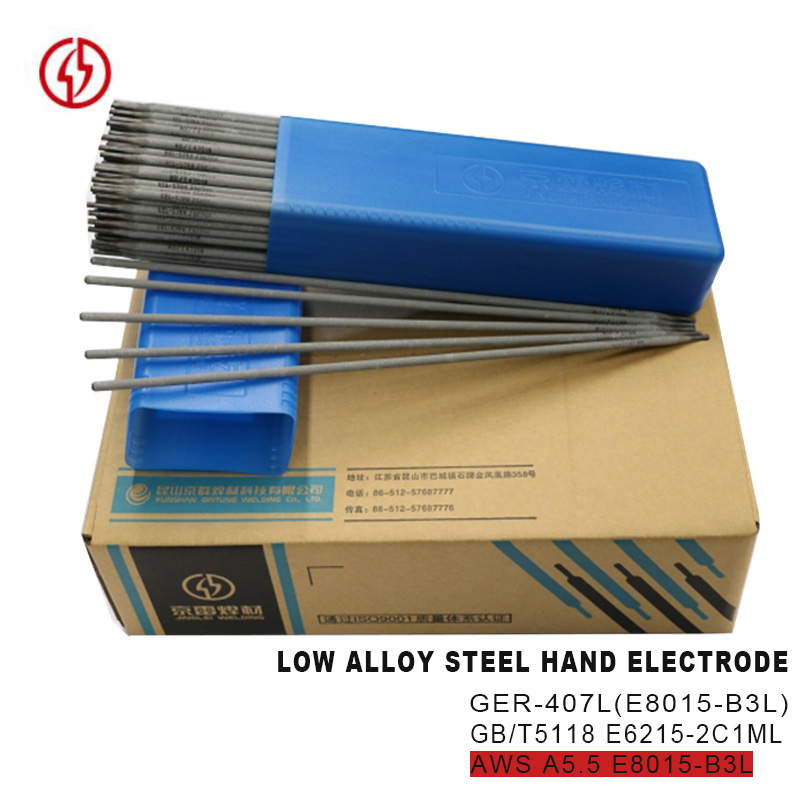

Halabuurka badeecada iyo soo bandhigida sifooyinka farsamada

QALABKA Kiimikada:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| XEERARKA GB/T | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| XEERARKA AWS | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| TUSAALE QIIMAHA | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

HANTIDA makaanikada:

| HANTIDA | XOOG BADAN (MPa) | XOOGGA KORDHINTA (MPa) | KULULKA℃xh | QIIMAHA IIMAPACT J/℃ | ELONGATION(%) | |||||||||

| XEERARKA GB/T | 390 | 490 | 620*1 | - | 22 | |||||||||

| XEERARKA AWS | 390 | 490 | 620*1 | - | 22 | |||||||||

| TUSAALE QIIMAHA | 477 | 570 | 620*1 | 150/Heerkulka caadiga ah | 28 | |||||||||

XILDHIBAANADA ALXANKA LAGU SOO TALIYEY:

| QAYBAHA DHUL-DHAQAALAHA (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| Koronto (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

FAAHFAAHINTA XIDHIIDHKA:

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||