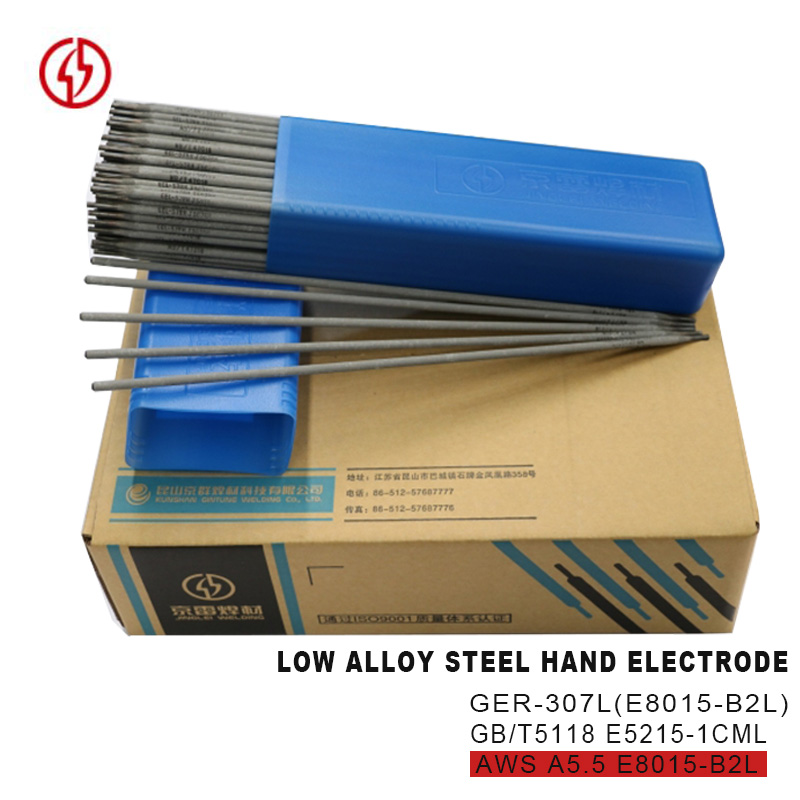

AWS E7015-B2L Biraha daawaha hooseeya ee gacanta

Codsiga&Standard&Ogaysiis:

AWS E7015-B2L kulaylka u adkaysta electrode ku haboon alxanka kulaylka kululeeyaha tube dusha iyo korontada derbiga biyaha, tuubada uumiga iyo weelka cadaadiska sare ee heerkulka ka hooseeya 550 ℃, sida saxan tube 15CrMo, A335-P11 tube, A387Gr.11 saxan. Oo waxaa loo isticmaali karaa alxanka tuurista 30CrMnSi, oo ku habboon munaasabadda shuruudaha ka kooban kaarboonka hooseeya. Intaa waxaa dheer, waxaa lagama maarmaan ah in preheat alxanka at heerkulka inter-channel of 160 ℃ ~ 190 ℃ inta lagu guda jiro alxanka, iyo 690 ± 15 ℃ * 1h daaweynta kulaylka waa in la fuliyaa si waafaqsan shuruudaha caadiga ah ee alaabta alxanka.

Astaamaha

AWS E7015-G2L(R307L) nooca kulaylka u adkaysta birta gacanta elektarooniga ah waa electrode gacanta nooca sodium hydrogen hooseeyo, arc xasiloon, daadsanaan yar, samaynta wanaagsan, sahal fudud, waxqabadka X-Ray waa heer sare ah. Waxay leedahay sifooyin farsamo oo deggan waxayna ilaalin kartaa adkaanta saameynta sare ee xaaladaha daaweynta kulaylka. Kuleyliyaha ka hor waa cabbir teknoloji oo muhiim ah oo alxanka dildilaaca qabow iyo baabi'inta diiqada birta u adkeysata kulaylka perlite. Si loo hubiyo tayada alxanka, iyada oo aan loo eegin habka loo marayo alxanka adag ama alxanka, waa in horay loo sii kululeeyaa oo la ilaaliyaa heerkul gaar ah. Kadib dhamaadka shaqada alxanka si alxanka qaboojinta gaabis ah, alxanka qaboojinta gaabis ah waa alxanka chromium-molybdenum birta u adkaysta kulaylka waa in si adag loo raaco mabda'a, xitaa xagaaga kulul waa in tan la sameeyaa, alxanka guud isla markiiba maro asbestos ah si loo daboolo alxanka iyo meel u dhow tolitaanka, qaybo yaryar oo alxanka ayaa lagu dhejin karaa marada asbestos si tartiib ah qaboojinta.

Shirkadda & Warshada

Halabuurka badeecada iyo soo bandhigida sifooyinka farsamada

QALABKA Kiimikada:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S | Ni |

| XEERARKA GB/T | 0.05 | 0.90 | 1.00 | 1.00-1.50 | 0.40-0.65 | 0.03 | 0.030 | - |

| XEERARKA AWS | 0.05 | 0.90 | 1.00 | 1.00-1.50 | 0.40-0.65 | 0.04 | 0.035 | - |

| TUSAALE QIIMAHA | 0.038 | 0.85 | 0.26 | 1.2 | 0.48 | 0.013 | 0.009 | 0.020 |

HANTIDA makaanikada:

| HANTIDA | XOOG BADAN (MPa) | XOOGGA KORDHINTA (MPa) | KULULKA℃xh | QIIMAHA IIMAPACT J/℃ | ELONGATION(%) | |||||||||

| XEERARKA GB/T | 390 | 520 | 690*1 | - | 17 | |||||||||

| XEERARKA AWS | 390 | 520 | 690*1 | - | 19 | |||||||||

| TUSAALE QIIMAHA | 450 | 550 | 690*1 | 185 / heerkulka dabiiciga ah | 28 | |||||||||

XILDHIBAANADA ALXANKA LAGU SOO TALIYEY:

| QAYBAHA DHUL-DHAQAALAHA (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| Koronto (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

FAAHFAAHINTA XIDHIIDHKA:

| QARINTA | DHEERAAD | PCS/1KG | Miisaanka/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||

Kiisaska caadiga ah

Shahaado

Halabuurka badeecada iyo soo bandhigida sifooyinka farsamada

QALABKA Kiimikada:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S | Ni |

| XEERARKA GB/T | 0.05 | 0.90 | 1.00 | 1.00-1.50 | 0.40-0.65 | 0.03 | 0.030 | - |

| XEERARKA AWS | 0.05 | 0.90 | 1.00 | 1.00-1.50 | 0.40-0.65 | 0.04 | 0.035 | - |

| TUSAALE QIIMAHA | 0.038 | 0.85 | 0.26 | 1.2 | 0.48 | 0.013 | 0.009 | 0.020 |

HANTIDA makaanikada:

| HANTIDA | XOOG BADAN (MPa) | XOOGGA KORDHINTA (MPa) | KULULKA℃xh | QIIMAHA IIMAPACT J/℃ | ELONGATION(%) | |||||||||

| XEERARKA GB/T | 390 | 520 | 690*1 | - | 17 | |||||||||

| XEERARKA AWS | 390 | 520 | 690*1 | - | 19 | |||||||||

| TUSAALE QIIMAHA | 450 | 550 | 690*1 | 185 / heerkulka dabiiciga ah | 28 | |||||||||

XILDHIBAANADA ALXANKA LAGU SOO TALIYEY:

| QAYBAHA DHUL-DHAQAALAHA (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| Koronto (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

FAAHFAAHINTA XIDHIIDHKA:

| QARINTA | DHEERAAD | PCS/1KG | Miisaanka/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||