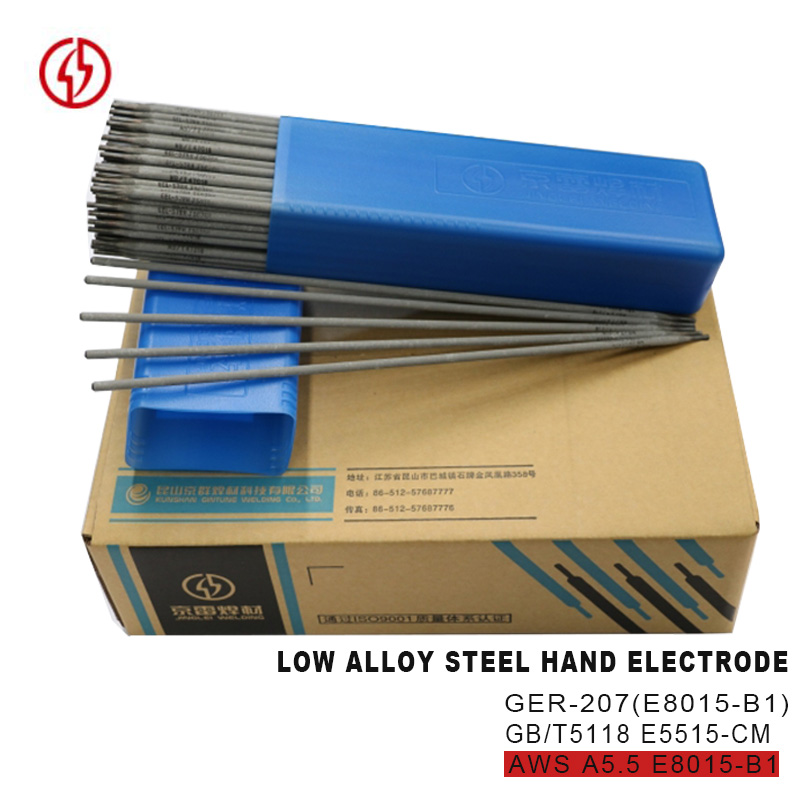

AWS E7018-A1 Biraha alxanka hooseeya ee birta silig alxanka budada ah Qalabka alxanka

Codsiga&Standard&Ogaysiis:

AWS E7018 -A1 Sida ASTM A204 iyo A335-P1 tuubooyinka; Alxanka waa in horay loo sii kululeeyaa ilaa 90-110 ℃ ka hor alxanka, oo ilaali heerkulka interlayerka. Waxa kale oo loo isticmaali karaa alxanka guud ee birta daawaynta hooseeysa qaab-dhismeedka birta xoogga sare. Iyo electrode gacanta waxaa loo isticmaali karaa alxanka booska buuxa. Marka loo eego sifooyinka habka wax soo saarka ee gaaska dareeraha ah ee heerkulka hooseeya, birta heerkulka hooseeya waxaa loo isticmaalaa darajooyin kala duwan iyadoo loo eegayo heerkulka adeegga ee kala duwan (-40 ℃, -70 ℃, -100 ℃, -194 ℃, -253 ℃ ), iyo alaabta alxanka u dhiganta ayaa la doortay.

Astaamaha

Qalabka noocan oo kale ah waa budada birta oo hooseeya nooca hydrogen-ga gacanta, ku daraya budada birta, waxtarka dhalaalka sare; 0.5% Mo waxaa lagu daraa si loo hagaajiyo xoogga alxanka iyo caabbinta daxalka; Oo qaansada waa xasiloon, yar daadinta, samaynta, wax ka gooyntu waa sahlan tahay, waxqabadka X-Ray waa fiican yahay.

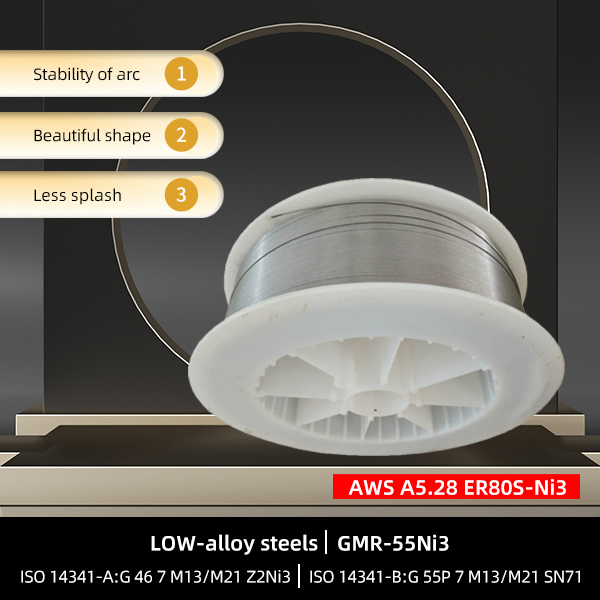

Walxaha isku-dhafka ah ee birta u adkeysata kulaylka pearlitic waa chromium, molybdenum, vanadium, niobium iyo wixii la mid ah si loo buuxiyo shuruudaha shaqada ee kala duwan. Sababtoo ah ficilka wadajirka ah ee walxaha daawaha carbon ee birta, way fududahay in la sameeyo qaab-dhismeed adag inta lagu jiro alxanka, iyo waxqabadka alxanka waa mid liita. Sidaa darteed, birta kulaylka u adkeysata ee pearlitic ayaa guud ahaan horay loo sii kululeeyay ka hor alxanka iyo xanaaqa alxanka ka dib.

Shirkadda & Warshada

Halabuurka badeecada iyo soo bandhigida sifooyinka farsamada

Halabuurka badeecada iyo soo bandhigida sifooyinka farsamada

QALABKA Kiimikada:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| XEERARKA GB/T | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| XEERARKA AWS | 0.12 | 0.90 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| TUSAALE QIIMAHA | 0.6 | 0.7 | 0.31 | 0.035 | 0.5 | 0.012 | 0.01 |

HANTIDA makaanikada:

| HANTIDA | XOOG BADAN (MPa) | XOOGGA KORDHINTA (MPa) | KULULKA℃xh | QIIMAHA IIMAPACT J/℃ | ELONGATION(%) | |||||||||

| XEERARKA GB/T | 390 | 490 | 620*1 | - | 22 | |||||||||

| XEERARKA AWS | 390 | 490 | 620*1 | - | 22 | |||||||||

| TUSAALE QIIMAHA | 480 | 570 | 620*1 | 170/Heerkulka caadiga ah | 26 | |||||||||

XILDHIBAANADA ALXANKA LAGU SOO TALIYEY:

| QAYBAHA DHUL-DHAQAALAHA (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| Koronto (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

FAAHFAAHINTA XIDHIIDHKA:

| QARINTA | DHEERAAD | PCS/1KG | Miisaanka/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||

Kiisaska caadiga ah

Shahaado

Halabuurka badeecada iyo soo bandhigida sifooyinka farsamada

QALABKA Kiimikada:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| XEERARKA GB/T | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| XEERARKA AWS | 0.12 | 0.90 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| TUSAALE QIIMAHA | 0.6 | 0.7 | 0.31 | 0.035 | 0.5 | 0.012 | 0.01 |

HANTIDA makaanikada:

| HANTIDA | XOOG BADAN (MPa) | XOOGGA KORDHINTA (MPa) | KULULKA℃xh | QIIMAHA IIMAPACT J/℃ | ELONGATION(%) | |||||||||

| XEERARKA GB/T | 390 | 490 | 620*1 | - | 22 | |||||||||

| XEERARKA AWS | 390 | 490 | 620*1 | - | 22 | |||||||||

| TUSAALE QIIMAHA | 480 | 570 | 620*1 | 170/Heerkulka caadiga ah | 26 | |||||||||

XILDHIBAANADA ALXANKA LAGU SOO TALIYEY:

| QAYBAHA DHUL-DHAQAALAHA (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| Koronto (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

FAAHFAAHINTA XIDHIIDHKA:

| QARINTA | DHEERAAD | PCS/1KG | Miisaanka/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||