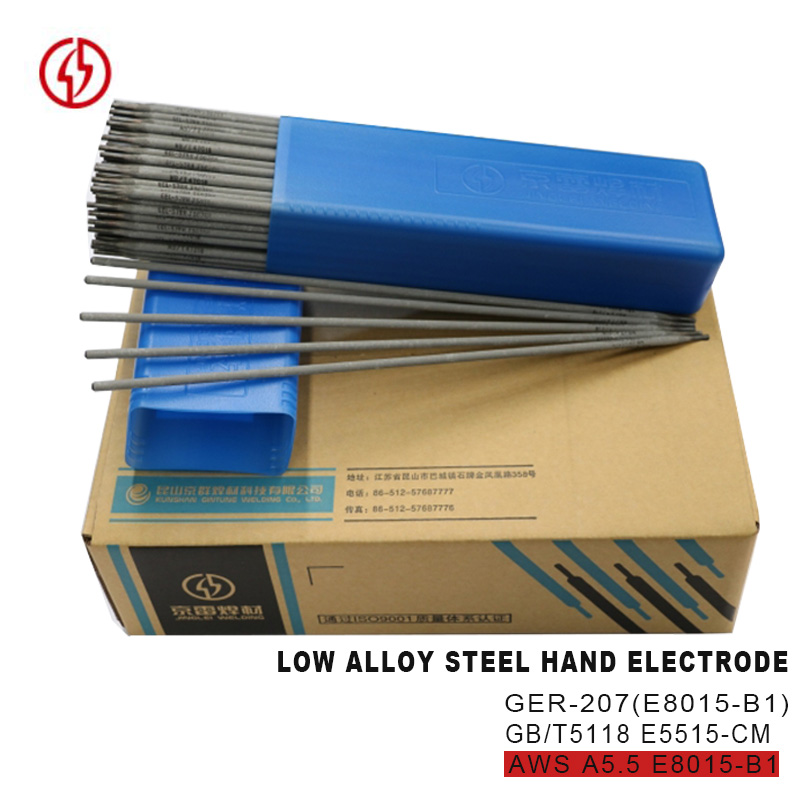

AWS E8015-B1 Biraha daawaha hooseeya ee gacanta

Codsiga&Standard&Ogaysiis:

Usha alxanka gacanta ee birta ah ee birta ah ee GER-207 (R207) 0.5%Cr-0.5% saxan tube, A335-P2 tube, A387Gr.2 saxan. Xaaladaha alxanka: preheating iyo kanaalka (lakabka) heerkulka: 160 ~ 190 ℃; 3. Daaweynta kuleylka: 690 ± 15 ℃x1h daaweynta kulaylka waxaa lagu fuliyaa si waafaqsan shuruudaha caadiga ah ee alaabta alxanka.

AWS E8015-B1 nooca gacanta electrode ee birta u adkeysiga kulaylku waxay ku habboon tahay alxanka CrMo pearlite birta u adkeysata kulaylka (sida 12CrMo, iwm.) iyo heerkulka sare, dhuumaha cadaadiska sare, weelka kiimikada iyo birta kale ee u dhiganta. Kahor alxanka, korantada waa in lagu dubo qiyaastii 350 ℃ 1 saac, ka dibna loo isticmaalo dubista. Alxanka ka hor, alxanka waa in laga nadiifiyaa miridhku, saliid, biyo iyo wasakh kale.

Astaamaha

AWS E8015-B1 (R207) nooca gacanta alxanka elektarooniga ah ee birta u adkeysiga kulaylku waa nooc sodium hydrogen ah oo hooseeya alxanka gacanta, arc deggan, daadinta yar, samaynta wanaagsan, sahal fudud, waxqabadka X-Ray waa mid aad u fiican. Qalabka alxanka gacanta waxaa si weyn loogu isticmaalaa awooda korantada, injineernimada awooda, petrochemical iyo warshadaha kale, nooca ugu badan ee la isticmaalo Cr-Moh iyo Mn-Mo nooca kulaylka u adkaysta iyo Cr-Mo base multi-element alloy kulayl u adkaysta birta. Waxa kale oo lagama maarmaan ah in la qaato habka preheating ka hor inta aan la dhigin alxanka iyo alxanka rasmiga ah ee alxanka birta u adkaysta kulaylka. Haddii alxanku uu xooggan yahay, waa in la sii kululeeyaa guud ahaan. Alxanka ka dib, alxanka waa in lagu hayaa meel ka sareysa kulaylka kahor dhowr saacadood, ka dibna si tartiib ah loo qaboojiyo.

Shirkadda & Warshada

Halabuurka badeecada iyo soo bandhigida sifooyinka farsamada

Halabuurka badeecada iyo soo bandhigida sifooyinka farsamada

QALABKA Kiimikada:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| XEERARKA GB/T | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| XEERARKA AWS | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| TUSAALE QIIMAHA | 0.078 | 0.72 | 0.35 | 0.56 | 0.53 | 0.016 | 0.01 |

HANTIDA makaanikada:

| HANTIDA | XOOG BADAN (MPa) | XOOGGA KORDHINTA (MPa) | KULULKA℃xh | QIIMAHA IIMAPACT J/℃ | ELONGATION(%) | |||||||||

| XEERARKA GB/T | 460 | 550 | 690*1 | - | 17 | |||||||||

| XEERARKA AWS | 460 | 550 | 690*1 | - | 19 | |||||||||

| TUSAALE QIIMAHA | 490 | 590 | 690*1 | 90/Heerkulka caadiga ah | 23 | |||||||||

XILDHIBAANADA ALXANKA LAGU SOO TALIYEY:

| QAYBAHA DHUL-DHAQAALAHA (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| Koronto (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

FAAHFAAHINTA XIDHIIDHKA:

| QARINTA | DHEERAAD | PCS/1KG | Miisaanka/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||

Kiisaska caadiga ah

Shahaado

Halabuurka badeecada iyo soo bandhigida sifooyinka farsamada

QALABKA Kiimikada:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| XEERARKA GB/T | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| XEERARKA AWS | 0.05-0.12 | 0.90 | 0.80 | 0.40-0.65 | 0.40-0.65 | 0.03 | 0.030 |

| TUSAALE QIIMAHA | 0.078 | 0.72 | 0.35 | 0.56 | 0.53 | 0.016 | 0.01 |

HANTIDA makaanikada:

| HANTIDA | XOOG BADAN (MPa) | XOOGGA KORDHINTA (MPa) | KULULKA℃xh | QIIMAHA IIMAPACT J/℃ | ELONGATION(%) | |||||||||

| XEERARKA GB/T | 460 | 550 | 690*1 | - | 17 | |||||||||

| XEERARKA AWS | 460 | 550 | 690*1 | - | 19 | |||||||||

| TUSAALE QIIMAHA | 490 | 590 | 690*1 | 90/Heerkulka caadiga ah | 23 | |||||||||

XILDHIBAANADA ALXANKA LAGU SOO TALIYEY:

| QAYBAHA DHUL-DHAQAALAHA (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| Koronto (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

FAAHFAAHINTA XIDHIIDHKA:

| QARINTA | DHEERAAD | PCS/1KG | Miisaanka/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16 PCS | 5KG | |||

| 5.0mm | 350mm | 12 PCS | 5KG | |||