Whatsapp:+8613252436578 E-mail:sale@welding-honest.com

1. kala saarid

Marka loo eego qaddarka ka kooban kaarboonka, birta kaarboon waxa loo qaybin karaa saddexda qaybood ee soo socda:

1) Bir kaarboon hoose C% ≤ 0.25

2) Bir kaarboon dhexdhexaad ah 0.25

3) Birta kaarboonka sare ee C%> 0.6

Kartoon hoose

Kaarboon-dhexe

Kaarboon-sare

2. falanqaynta weldability

Qadarka ka kooban kaarboonku waa tixraac muhiim u ah horumarinta hababka alxanka. Marka maaddada kaarboonku korodho, xoogga iyo adayggu way kordhaan, halka caagga iyo adkaanta ay hoos u dhacaan, halka diiqadu korodho. Marka la eego, hoos udhaca kaarboonka, alxanka wanaagsan, sidaa darteed, kaarboonku waa halbeegga lagu xukumayo dhibka alxanka kaarboonka, iyo hababka alxanka ee kala duwan waa in loo qaataa kaarboonka kala duwan.

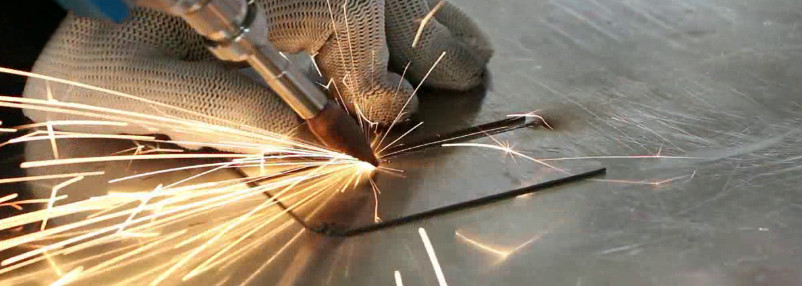

3. Habka alxanka

Doorashada qalabka alxanka birta kaarboon waxay raacdaa mabda'a "xoog siman"

1. Bir kaarboon yar (badanaa loo yaqaan bir khafiif ah)

Darajooyinka birta ee caadiga ah sida Q235 (oo hore loogu yiqiin A3 steel), Q255, iwm., guud ahaan ma qaadaan tillaabooyin gaar ah marka alxanka, aan horay u kululayn ama dib u kululayn.

2. Bir kaarboon dhexdhexaad ah

Birta sida caadiga ah loo isticmaalo sida 30#, 45#, iwm, 45# waa agabka wax lagu farsameeyo miinshaarta iyo faylalka, waxa fiican in la isticmaalo alxanka hydrogen-ka hooseeya oo leh iska caabin dildilaac ah oo wanaagsan, preheating 100-200 °C; Haddii aysan ku habboonayn in la sii kululeeyo, Cr-Ni austenitic birta alxanka waa la dooran karaa.

3. Bir kaarboon sare leh

Darajooyinka birta sida caadiga ah loo isticmaalo sida 60Si2Mn, T8, T10 iyo wixii la mid ah. 60Si2Mn waa birta guga caadiga ah, guud ahaan ma fuliyaan daawaynta alxanka, inta badan loo isticmaalo dib-u-alxanka, waa in ay ahaataa 250-350 °C preheating, alxanka waa in la garaacaa si loo baabi'iyo walbahaarka, iyo 650 °C daaweynta kulaylka ka dib, sidoo kale dooro Cr-Ni austenitic ahama alxanka alaabta

Afaraad, birta khafiifka ah ee gacanta electrode guud alxanka aasaasiga ah:

Heerkulka qalajinta korantada

| Shayga | Nooca maqaarka | Alaabta | Heerkulka | Waqtiga |

| Bir kaarboon yar iyo birta xoogga badan | Nooca hydrogen-ka hooseeya | E7016, E7048, E7015, E7015-G | 300-350 ℃ | 60min |

| E7015, E8015-G, E9016-G, E9015-D1, E10015-D2, E12015-G | 330-380 ℃ | |||

| Adayg sare iyo nooca hydrogen hooseeyo | E7016-G, E7015-G, E8015-G, E9015-G, E10015-G | 350-380 ℃ | 60min | |

| Budada birta nooca hydrogen hooseeyo | E7018, E7018-1 | 300-350 ℃ | 60min | |

| E8018-G, E918-G, E9018-M, E10018-D2, E10018M, E11018-G, E11018M, E12018-G | 350-380 ℃ | 60min |

2. Qoyaanka, saliidda, miridhku, iwm ee dusha sare ee alaabta saldhigga ah waa in la saaraa

3. Isticmaal habka gadaal-u-socod si aad alxanka uga ilaaliso stomata barta bilowga

Alxanka gaagaaban waa in la isticmaalaa, sida xariijimaha oscillating, iyo baaxadda oscillation waa in aanay ka badnaan 3 jeer dhexroorka siliga.

Waqtiga boostada: Oct-13-2022